WIND TURBINE

Wind energy

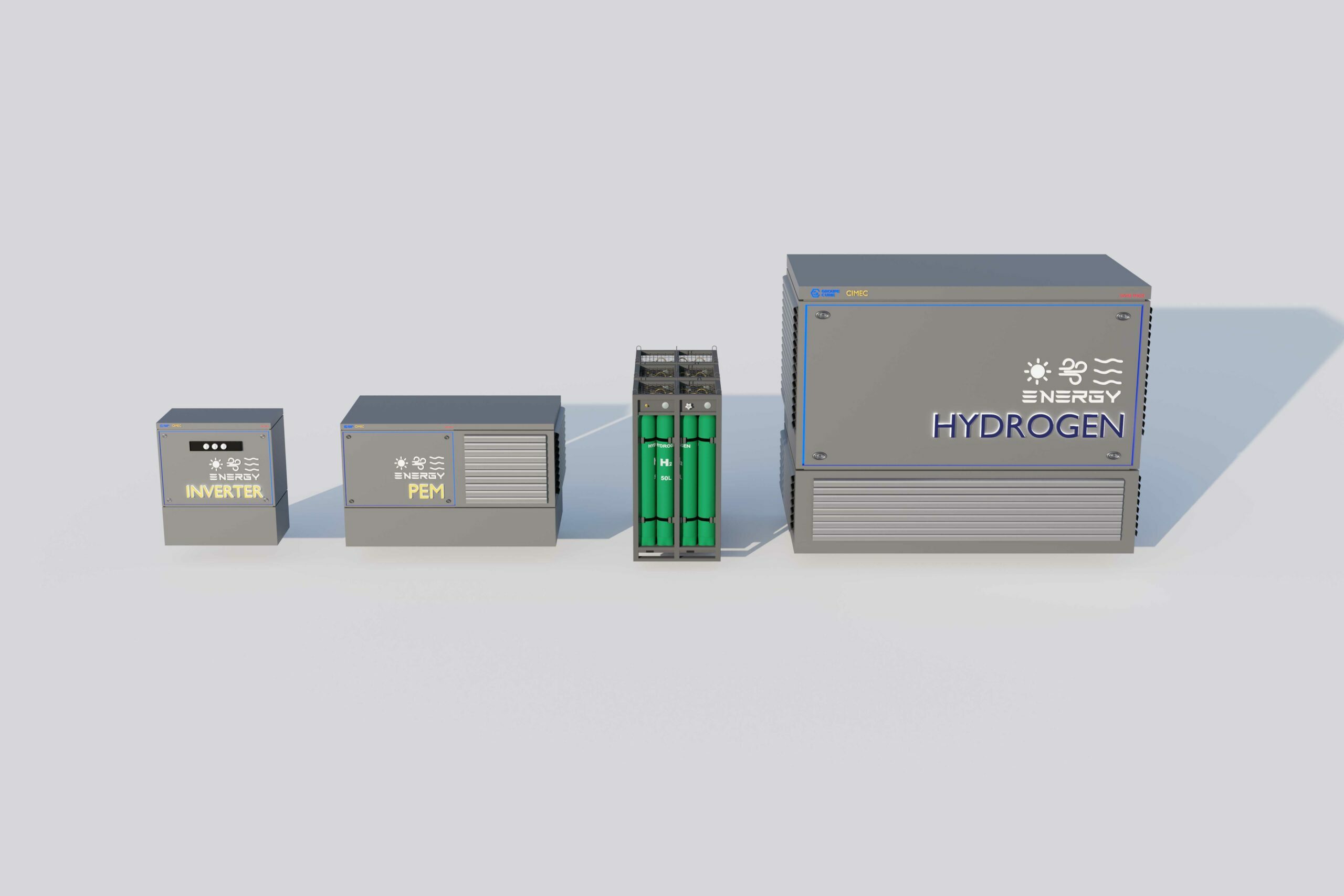

Hydrogen GENERATOR

Emergency generator

SOLAR PANELS

F.L.P. Technology

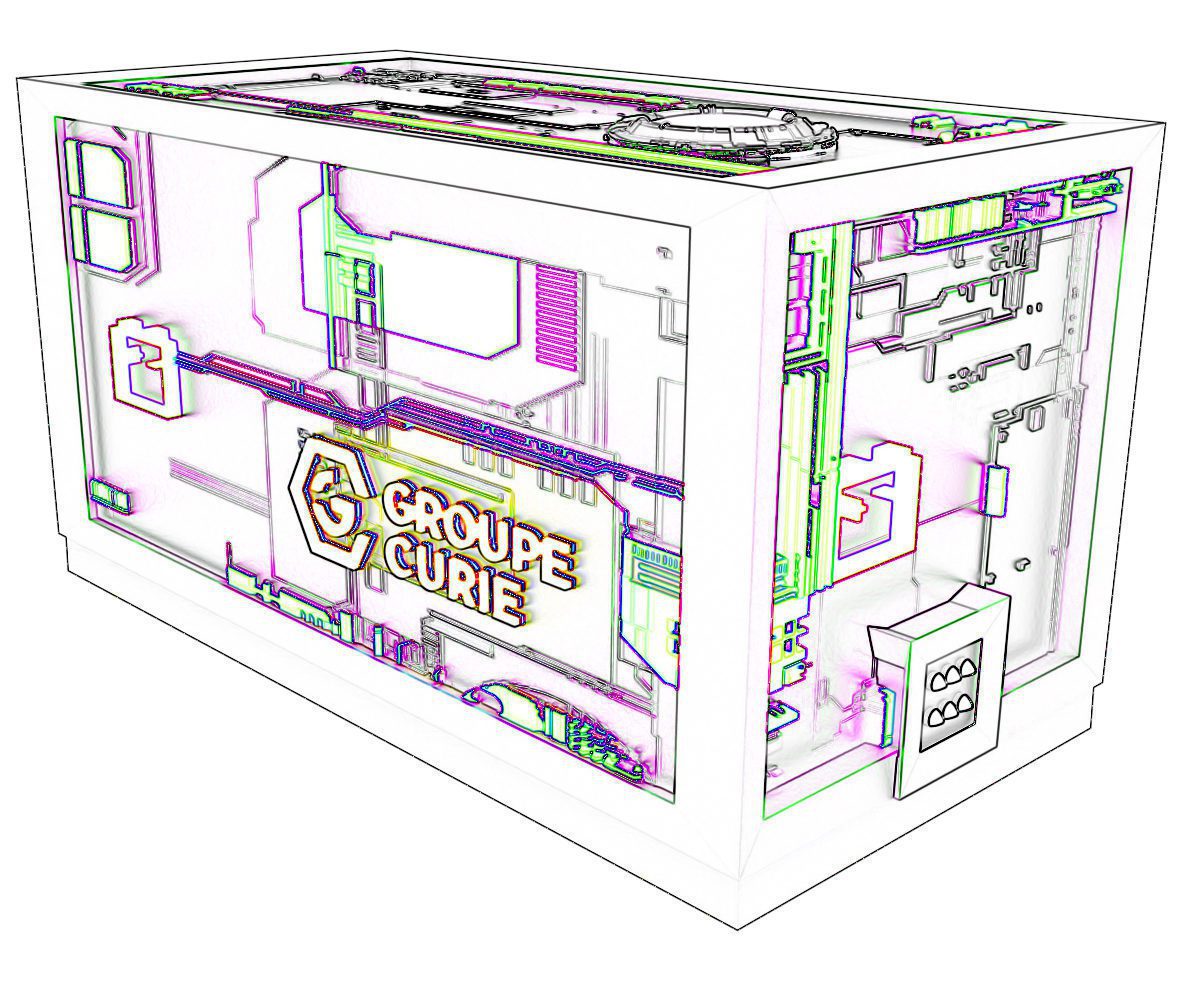

INDUSTRIAL BATTERIES

Smart industrial energy storage

Building a new chemical plant requires a range of technological knowledge AND HUGE experience in chemistry !

GREEN TECHNOLOGIES MADE IN EUROPE !

Groupe Curie develops and operates breakthrough and highly efficient green technologies in collaboration with engineering partners! The primary goal is to achieve high yield and efficiency from energy production onwards. Sustainability has never been more important to business planning, management and operations – and it has never been more likely to produce measurable results. Yes, it’s imperative to reduce carbon footprints and environmental impacts. And in many regions, there are government regulations and green incentives to do so. But beyond that, the opportunities that IoT and connectivity offer to improve business efficiency and reduce costs mean that investing in green technology is not only the right thing to do, it also makes good business sense.

SOLAR PANEL WITH INNOVATIVE TECHNOLOGY till 20% more efficient than average!

Advanced technology achieve an overall efficiency increase of over 20%

compared to the competition. Groupe Curie ist are able to achieve significantly more energy per unit of time than the competition. More kilowatts also means higher hydrogen production, which in turn has a positive effect on

yields !

Smart Solar Panel

Hybrid solar tracking system with F.L.P. Technology for 30% more energy than average ! Made in Europe!

Solar Tracking

hybrid-solar tracking and positioning system optimized by Groupe Curie Engineers.

Hybrid technology

Hybrid Technology for higher efficiency and smart grid energy distribution.

Bi-Facial modules

Advanced special coated Bi-Facial solar modules which achieve an efficiency increase of over 30% .

special coating

Special coating, increase energy production for industrial use.

WIND TURBINE MADE IN EUROPE, DEVELOPED 100% BY GROUPE CURIE !

In order to meet the increased energy demand for ammonia production also overnight and in the winter months, a new turbine was developed by Groupe Curie Engineering team, which generates electricity even with very low wind forces and is able to compensate for wind fluctuations. The turbine will be built from sustainable materials to minimize CO2 emissions even with the materials used.

Hybrid Wind Turbine

Revolutionary, High Efficiency Wind Turbine with approx 60% more energy than average industrial design ! – Patented Design and Technology !

HIGH EFFICIENCY +40%

SMART GRID «Hybrid-Wind Turbine», optimized for continuous green ammonia production !

SUSTAINABLE modular DESIGN

Constructions elements are made from sustainable material.

OPTIMIZED FOR GREEN HYDROGEN

«Hybrid-Wind Turbine», optimized for hybrid-green hydrogen production !

24H ENERGY PRODUCTION

More energy is available per unit of time and thus higher profits are achieved.

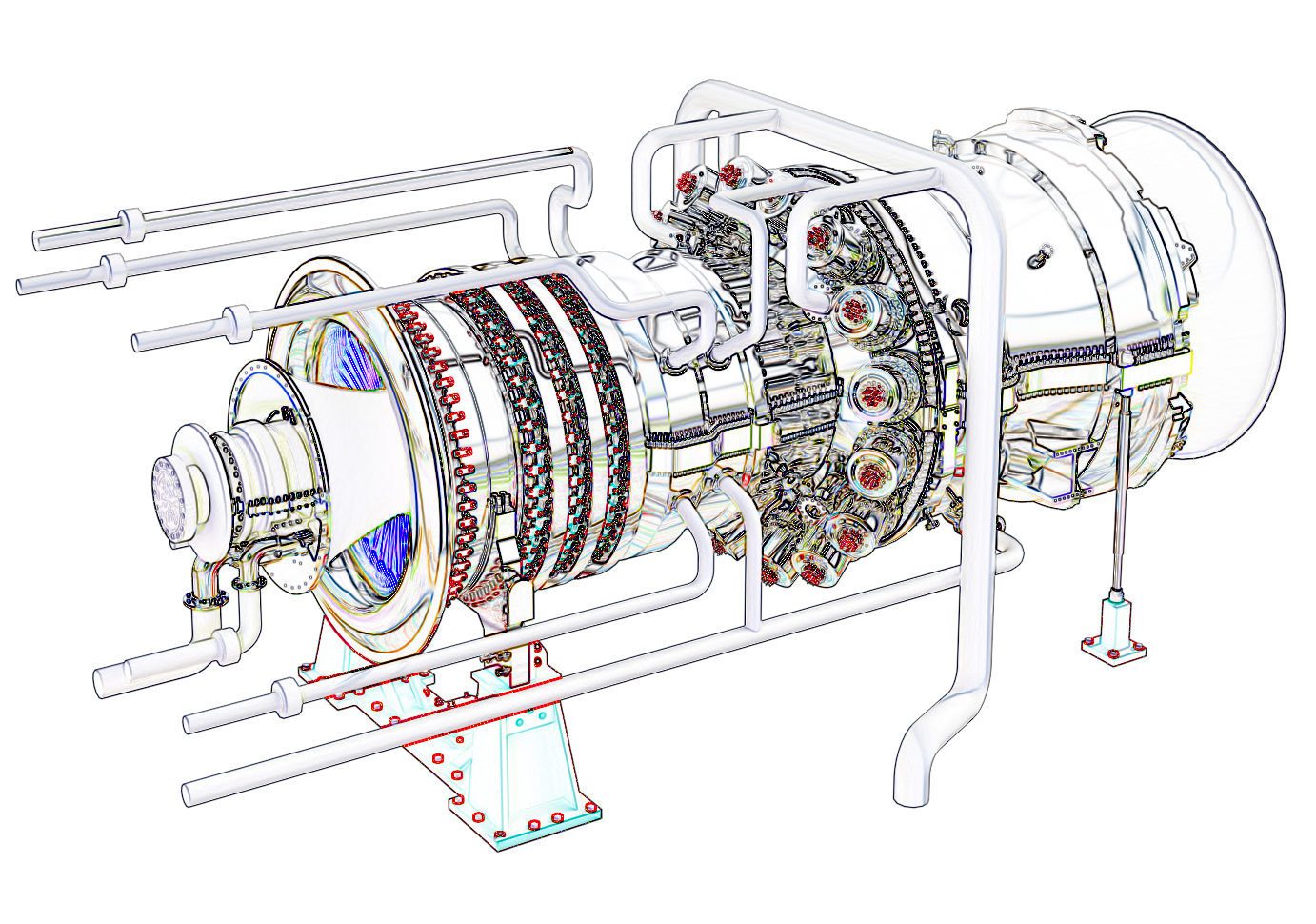

hydrogen turbine as

emergency power generator

To ensure a continuous power supply for the self-sufficient production operation and the ammonia reactor, we use a hydrogen turbine specifically dedicated for this purpose. Groupe Curie relies on a power supply that is separate and independent from the grid. The excess electricity that cannot be collected by the industrial batteries is fed into the public grid.

Hydrogen Generator System

Optimized for the high demand of energy!

HYDROGEN GENERATOR

Uninterruptible power supply during electricity fluctuations.

STORAGE OF HYDROGEN

Prevents the reactor from shutting down in the event of supply bottlenecks.

PEM

Re-Converting Hydrogen in Energy.

INverter

Inverter converts direct current (DC) electricity into alternating current (AC) electricity

hydrogen turbine as

emergency power generator

To ensure a continuous power supply for the self-sufficient production operation and the ammonia reactor, we use a hydrogen turbine specifically dedicated for this purpose. Groupe Curie relies on a power supply that is separate and independent from the grid. The excess electricity that cannot be collected by the industrial batteries is fed into the public grid.

Hydrogen Generator Turbine

Optimized for the ammonia reactor demand of energy!

Hybrid generator turbine

Uninterruptible power supply during electricity fluctuations.

Compensate Energy bottlenecks !

Prevents the reactor from shutting down in the event of supply bottlenecks.

Stabilize Ammonia production!

Higher ammonia production!

Indipendence from fossil fuels!

Carbon free energy production when necessary.

SMART INDUSTRIAL BATTERIES

When it comes to sustainability, it’s important to take a closer look, because it’s not just about recycling, but also about the availability and degradation of raw materials. Both the individual cells and the entire salt battery are made of materials that can be recycled after 10 years of use in stationary electricity storage. The recycling of salt batteries has already been standardized and industrialized for 15 years. The metals are melted down and returned to the metal industry.

Smart Industrial Batteries

Organic based industrial battery with similar energy density as lithium-ion batteries !

LOW MAINTENANCE

General maintenance every 15 years !

NON-TOXIC DESIGN

Pollutant and toxic free organic based industrial batteries and harmless to the environment!

HIGH RESIDUAL CAPACITY

Residual capacity is still 100% even after years !

LIFECYCLE DESIGN

The batteries are completely renewed every 15 years and are then 100% efficient!

Green Ammonia production

Synthesis loop – Haber-Bosh Process

(We are using brand-new ammonia converter to provide better conversion reactor to avoid greenhouse gas emissions!)

From High-Pressure Steam over the heat exchanger to to liquid ammonia.

To produce the desired end-product ammonia from the a complex interconnected system, the hydrogen (H2) is catalytically reacted with nitrogen(N2) in the synthesis reactor (ammonia converter) operated at high-pressure levels to form anhydrous liquid ammonia.

The hot gas leaving the ammonia converter is cooled and ammonia is separated from the recycle gas. Unconverted synthesis gas is supplemented with fresh mixture of hydrogen and nitrogen and returned as feed to the ammonia synthesis reactor.

SOEC (Solid Oxide Electrolysis Cells)

SOEC – High Temperature Electrolyser

(We are using innovative SOEC Electrolyzer with an efficiency 25% higher than average)

From splitting H2O(Water) in H2(Hydrogen) and O2(Oxygen) molecule to delivering H2 to Synthesis Loop

The SOEC Stacks of Groupe Curie converts steam and/or carbon dioxide directly into hydrogen gas, carbon monoxide, and oxygen.

Solid oxide electrolysis cells (SOECs) are a type of electrochemical device that can be used to produce

hydrogen gas through the process of electrolysis.

They have several advantages compared to other electrolysis technologies:

- High efficiency: SOECs can achieve high electrolysis efficiencies due to their high operating temperatures (600-1000°C), which allows for a more thermodynamically favorable reaction.

- Durability: SOECs are made of solid, ceramic materials that are resistant to corrosion and can operate for long periods of time without degrading.

- Versatility: SOECs can be used to produce hydrogen from a variety of feedstocks, including water, natural gas, and biomass.

- Low cost: SOECs have the potential to be more cost-effective than other electrolysis technologies due to their high efficiency and the abundance of materials that can be used to make them.

- Environmental benefits: SOECs produce hydrogen with minimal greenhouse gas emissions, making them a potentially attractive option for producing clean hydrogen for use in fuel cells or as a chemical feedstock.

In comparison to AWE and PEM, our technology has two main advantages:

1. It has a higher conversion efficiency due to favorable thermodynamics and kinetics at higher operating temperatures.

2. SOEC can be integrated with a range of existing down-stream industrial processes.

This will result in the generation of synthetic fuels, methanol, ammonia and recycling of captured carbon dioxide.